Berkeley Puncher 850

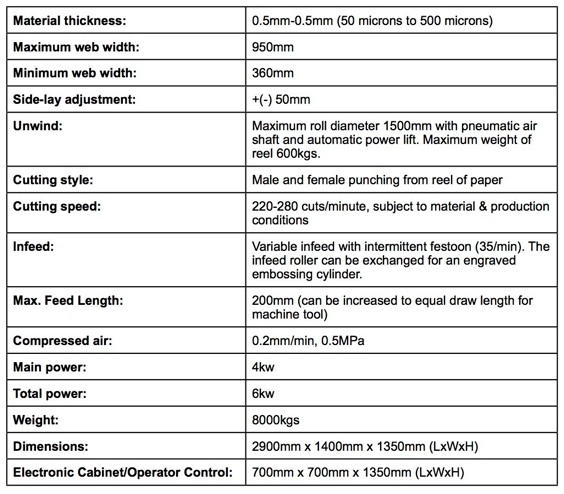

Automatic punching/cutting machine to cut a wide range of paper and laminate profiles. The machine operates through a high speed platen processing unit using male and female dies. The waste is extracted automatically through the cycle of the production of profiles.

The operation of the machine is assisted by a PLC micro-electronic control system and LCD visual display with electronic optical tracking for pre-printed material and automatic compensation technology for length feeding control. The controls are easily displayed through an operator control panel and allows for accurate production of the cut/punched profiles. The length adjustment and electronic controls are driven by servo motors.

Machine's working conditions:

Environmental temperature: -1 - 35ºC

Air relative humidity is less than 85%

The fluctuation of power supply and voltage must not exceed 10%

© 2011 Berkeley Machinery. All rights reserved.

Website designed by Liana Berkeley-Hill

Berkeley Puncher 850

High Speed Punching Machine